A B2B Guide for Hospitality & Foodservice Procurement

I. The Urgent Imperative for Sustainable Solutions in Hot Beverage Service

The landscape of B2B procurement is undergoing a seismic shift, driven by escalating environmental regulations and a global push for sustainability. For businesses operating in the beverage sector, this transformation presents a critical juncture, particularly concerning single-use plastics. Regulatory bodies worldwide are enacting stringent bans, exemplified by Victoria, Australia, which prohibited single-use plastic straws from February 1, 2023, and the UK, following suit from October 7, 2024. These mandates create an urgent imperative for businesses to seek out compliant, high-performance alternatives.

A significant operational challenge emerges when addressing hot beverages: traditional paper straws often falter, rapidly becoming soggy and disintegrating, which severely compromises the customer experience. This ubiquitous “soggy straw” dilemma has created a glaring market gap, demanding innovative solutions that can withstand high temperatures without degradation. Furthermore, businesses face immense pressure to align their operations with burgeoning consumer demand for sustainable practices and evolving ESG (Environmental, Social, and Governance) procurement policies. Failure to adapt not only risks regulatory non-compliance and associated fines but also significant reputational damage in a market increasingly valuing environmental stewardship. The financial implications of this shift are substantial; the global sustainable packaging market, a segment directly impacting straw alternatives, is projected to surge from USD 316.8 billion in 2024 to USD 662.4 billion by 2034, demonstrating a robust 7.6% Compound Annual Growth Rate (CAGR). This trajectory underscores the commercial viability and strategic importance of investing in advanced eco-friendly solutions.**Embrace heat-resistant eco-friendly straws to meet regulations and enhance customer satisfaction in hospitality.**

II. Navigating the Regulatory Landscape and Market Demands for Heat-Resistant Eco-Friendly Straws

Evolving Plastic Bans and Their Operational Impact: Beyond the EU PPWR Mandate

The global legislative drive against single-use plastics is intensifying, fundamentally reshaping procurement and supply chain decisions for businesses across industries. Beyond national and regional bans, overarching regulations like the EU Packaging and Packaging Waste Regulation (PPWR) are mandating that all packaging placed on the EU market must be reusable or recyclable by 2030. These directives are not merely suggestions; they are legally binding requirements compelling brands to embed sustainable alternatives into their core operations.

The scope of these bans is broad, encompassing all types of single-use plastic, whether conventional, biodegradable, compostable, or recycled, and even items partly made from plastic, including those with plastic coatings or linings. For instance, the Victorian Government’s 2023 ban on single-use plastic drinking straws applies universally, with specific exemptions only for individuals with disabilities or medical needs. Similarly, the UK’s 2024 ban includes drink products with attached plastic straws but exempts those used as packaging for items like medicines. Businesses that fail to navigate these complex and evolving regulations face not only substantial fines but also severe reputational damage among a public increasingly aware of corporate environmental responsibility. To fully understand the shift towards greener options in the beverage sector, explore our comprehensive guide oneco-friendly straws for restaurants.

The Growing Sustainable Packaging Market & Why Hot Beverage Straws are Key

The momentum behind sustainable packaging is undeniable, driven by a confluence of heightened consumer awareness, ambitious corporate sustainability targets, and the global adoption of circular economy principles. This market is experiencing rapid growth, with paper and paperboard materials projected to dominate, holding an estimated 42% market share in 2025. This surge is buoyed by government campaigns and a widespread transition among Fast-Moving Consumer Goods (FMCG) brands seeking to reduce their dependency on traditional plastics.

North America, for example, accounted for approximately 33% of the global sustainable packaging revenue in 2024, signaling a strong market readiness and demand for eco-friendly solutions. While challenges such as higher production costs for sustainable materials and potential raw material limitations persist, larger corporations are increasingly absorbing these expenses as part of their long-term strategic commitments. The focus on hot beverage straws within this market segment is critical, as it represents a persistent pain point that standard paper or first-generation bioplastic straws have struggled to address. Innovations in this niche are not just about compliance but about enhancing customer experience and reinforcing brand value in a competitive environment.**Global plastic bans and market growth demand compliant, high-performance hot beverage straw alternatives for hospitality.**

III. Breakthrough Materials in Heat-Resistant Eco-Friendly Straws

The quest to overcome the “soggy straw” dilemma in hot beverages has spurred significant advancements in material science, leading to a new generation of heat-resistant, eco-friendly straws. These innovations are critical for businesses aiming to meet both consumer expectations and regulatory mandates.

Advanced Bioplastics: Solving the “Soggy Straw” Dilemma at High Temperatures

Traditional polylactic acid (PLA) straws, while biodegradable, have historically suffered from a low heat deflection temperature (HDT), typically deforming above 40°C (104°F). This limitation has rendered standard PLA unsuitable for hot beverages. However, recent breakthroughs in bioplastic engineering are revolutionizing this.

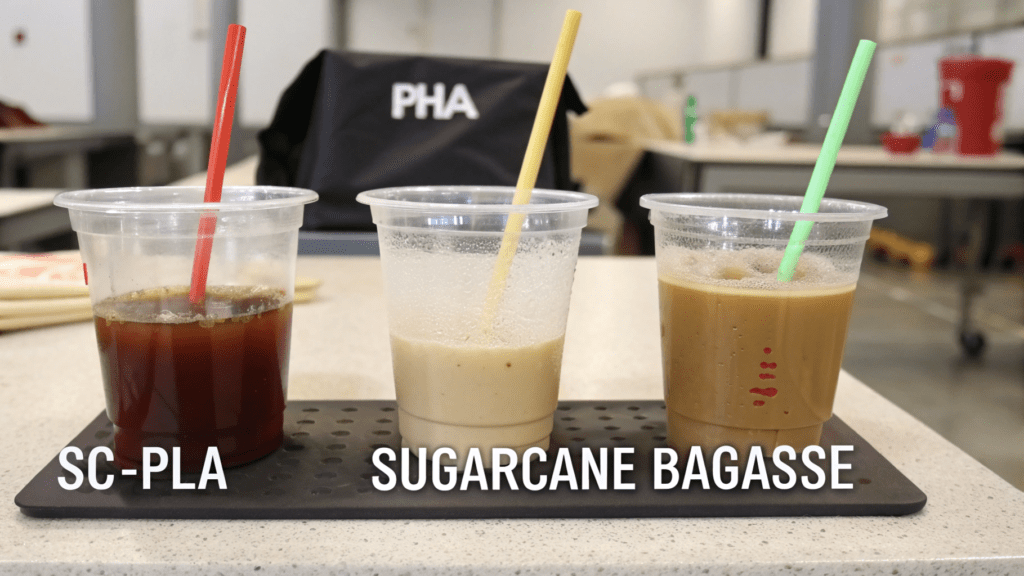

- Stereocomplexed Poly(lactic acid) (SC-PLA) straws represent a significant leap forward. Research indicates that SC-PLA straws remain remarkably stable even after immersion in 100°C water for 10 minutes, with only minimal loss of tensile strength. These straws are fully biodegradable and meet stringent compostable standards such as BPI (ASTM D6400) and TÜV Austria (EN 13432), offering a premium feel and robust performance in hot liquids.

- Evanesce offers innovative plant-based straws that are heat-resistant up to 80°C. These are 100% commercially compostable and engineered to be free of harmful PFAS chemicals and microplastics, providing a safe and sustainable solution.

- Zein straws, derived naturally from corn, rice, and other grains, demonstrate excellent biocompatibility and stability in boiling water, offering a truly natural and highly functional alternative.

- Furthermore, advanced PLA options are now being developed that can withstand temperatures exceeding 70°C, with some formulations even surpassing 100°C. These advancements often involve specialized crystallization (CPLA, which can handle up to 82°C) or blending with other polymers to enhance thermal properties, directly addressing the historical heat limitations of bioplastics.

- Polyhydroxyalkanoates (PHA) straws are another promising plant-based bioplastic, offering durability comparable to traditional plastic. PHAs are notable for their resistance to sogginess across various beverage temperatures and are uniquely marine degradable, in addition to being home and industrially compostable, future-proofing investments for businesses.

Natural Fibers: Sustainable Straws for Hot Beverages that Deliver Durability

Beyond advanced bioplastics, natural fiber-based straws are proving their mettle in hot beverage applications, offering both sustainability and surprising durability.

- Sugarcane (Bagasse) straws, made from the fibrous residue left after sugarcane juice extraction, are highly durable. They can handle temperatures up to 220°F (100°C) and resist sogginess for extended periods, making them a sturdy and reliable choice for hot drinks. They are often certified compostable, widely accepted by commercial composting facilities.

- Rice straws, crafted from rice flour and tapioca starch, provide an innovative, edible, and biodegradable option. They can withstand temperatures up to 60°C (140°F) for 2-3 hours before softening, offering a unique and sustainable drinking experience.

- Wheat straws, derived from natural wheat stems, are naturally heat-resistant and prove more durable than many paper alternatives. They are 100% compostable and represent a zero-waste solution by utilizing an agricultural byproduct.

- Innovative materials such as lignin and citric acid-based “thermoset films,” derived from edible starch and polyvinyl alcohol, show enhanced hydrostability and superior tensile strength, outperforming traditional paper and even some plastic straws in functionality.

- Other notable natural alternatives include Agavenstrohhalme, made from upcycled agave fibers, which are durable, plastic-free, and designed to maintain their structure in hot and cold drinks, biodegrading within 12 months. Coffee straws, produced from recycled coffee grounds, are odorless, tasteless, and free from toxins. Additionally, reed straws offer natural water resistance and sturdiness, breaking down naturally in diverse environments.

**New bioplastics and natural fibers offer durable, heat-resistant, and compostable straw solutions for hot beverages.**

IV. Comparing Heat-Resistant Eco-Friendly Straws: A B2B Procurement Guide

Choosing the right heat-resistant eco-friendly straw requires a strategic evaluation of operational impact, compliance, and return on investment. The following comparison highlights key considerations for procurement managers, operations directors, and sustainability officers.

| Besonderheit | B2B Betriebswirkung | Compliance Note | ROI -Potenzial |

|---|---|---|---|

| SC-PLA | Superior integrity in hot liquids (>100°C), offering a premium drinking experience. Maintains shape and structure longer, reducing customer complaints. | Fully biodegradable, certified compostable to rigorous standards like BPI (ASTM D6400) and TÜV Austria (EN 13432). Aligns with EU PPWR and global plastic bans. | Enhances brand image as a leader in sustainability, supports premium pricing. Reduces waste disposal costs in commercial composting. Contributes to higher customer satisfaction and repeat business due to superior performance. |

| Zuckerrohr (Bagasse) | Highly sturdy for hot drinks (up to 100°C), provides a natural, rustic aesthetic. Resists sogginess for extended periods, suitable for various hot beverages. | Certified compostable, widely accepted by commercial composting facilities. Complies with most single-use plastic bans, offering a reliable, mass-market compliant option. | Cost-effective for bulk procurement, balancing sustainability with budget. Meets core sustainability mandates for large-scale operations. Strong consumer appeal due to natural origin, improving brand perception and driving eco-conscious purchasing. |

| Advanced Paper | Significantly improved durability over standard paper straws, reducing “soggy straw” complaints. Widely available and familiar to consumers. Still may soften with very prolonged exposure to extreme heat. | Generally biodegradable; however, industrial composting may be required for some variants depending on coatings. Compliance varies based on specific regional regulations for “single-use plastics” (some bans include *all* types of single-use, even paper). | Lower initial investment compared to other advanced alternatives, facilitating widespread adoption. Addresses direct “soggy straw” feedback. Can be a stepping stone towards more advanced bioplastics while meeting immediate environmental pressures. |

| PHA | Provides durability and feel comparable to traditional plastic across a versatile temperature range. Offers consistent performance for various hot beverage types without compromising integrity. | Notable for being marine degradable, in addition to home and industrially compostable. Represents a significant step towards a circular economy, aligning with future regulatory trends. | Represents a future-proof investment given its broad degradability. Offers strong environmental credentials, appealing to a niche but growing segment of highly eco-conscious consumers. Reduces long-term environmental liability. |

| Wheat/Rice Straws | Wheat straws are naturally heat-resistant and more durable than paper. Rice straws withstand up to 60°C for 2-3 hours and are edible, offering a unique customer experience. Both are lightweight. | Both are 100% compostable and truly biodegradable. Wheat straws use an agricultural byproduct, while rice straws are edible, eliminating waste. High compliance with natural material bans. | Very low environmental footprint, enhancing brand authenticity. Can be a cost-effective choice for specific use cases. The novelty of edible straws or the natural appeal of wheat can create unique marketing opportunities and customer delight. |

**Evaluate heat-resistant eco-friendly straws based on operational impact, compliance, and ROI for optimal procurement.**

V. Certifications and Standards: Ensuring Compliance and Trust

For decision-makers, navigating the array of eco-friendly straw options requires a clear understanding of the certifications and standards that guarantee both compliance and product integrity. Verifying these credentials is paramount to safeguarding brand reputation and operational continuity.

Navigating Compostability Standards for Biodegradable Straws High Temperature

The term “eco-friendly” can be broad, making robust certifications essential for validating claims of biodegradability and compostability. These standards ensure that products truly break down without leaving harmful residues, differentiating genuine sustainable solutions from greenwashing.

- Biodegradable Products Institute (BPI): In North America, BPI is a leading certification body. Products certified by BPI meet the rigorous ASTM D6400 or ASTM D6868 standards, ensuring they will break down completely and safely in commercial composting environments. This certification is critical for businesses that dispose of waste via industrial composting facilities.

- TÜV Austria: A prominent European certification body, TÜV Austria offers “OK Compost INDUSTRIAL” and “OK Compost HOME” certifications. These verify compliance with European Bioplastics requirements and the EN 13432 standard for industrial composting, or for specific materials, suitability for home composting conditions.

- Australasian Bioplastics Association (ABA): For businesses operating in Australia and New Zealand, the ABA’s “Certified Compostable” trademark is key. Products certified to AS4736 (for industrial composting) require 90% biodegradation within 180 days and 90% disintegration within 12 weeks, ensuring high performance in managed waste streams.

- Der Compost Manufacturing Alliance (CMA) also plays a vital role by collaborating with commercial composting facilities to verify that products meet ASTM lab standards through combined lab and field tests, providing additional assurance of real-world performance. Businesses can reference the BPI website for a comprehensive list of certified compostable products and materials at bpiworld.org.

Food Safety Regulations and Responsible Sourcing

Beyond environmental degradation, the safety of food contact materials is non-negotiable.

- FDA Approval: For products sold in the United States, Food and Drug Administration (FDA) approval is crucial. This ensures that the materials used in heat-resistant eco-friendly straws are non-toxic, do not leach harmful chemicals into beverages, and are safe for direct food contact.

- Chemical Safety: Businesses must ensure that their chosen straw alternatives are free from harmful chemicals such as BPA (Bisphenol A) and PFAS (per- and polyfluoroalkyl substances). These “forever chemicals” pose long-term health and environmental risks and are increasingly under regulatory scrutiny.

- Ethical Sourcing: Responsible sourcing practices extend beyond environmental impact to encompass the social aspects of production. Look for certifications or supplier commitments that confirm ethical labor practices, fair wages, and transparency throughout the supply chain. This enhances brand reputation and mitigates supply chain risks.

**Certifications like BPI and FDA approval are crucial for ensuring compliant, safe, and trustworthy eco-friendly straws.**

VI. Operationalizing Sustainability: Case Study & Strategic Advantages

The shift to heat-resistant eco-friendly straws is not merely a compliance burden but a strategic opportunity to enhance brand value, streamline operations, and build lasting customer loyalty.

Mini Case Study: The “Eco-Brew” Chain’s Hot Beverage Straw Transition

The “Eco-Brew” chain, a major player in the coffee service industry, faced significant challenges stemming from consumer dissatisfaction and evolving regional regulations. Their traditional paper straws for hot beverages were a constant source of complaints, becoming soggy and degrading quickly, undermining the premium coffee experience they aimed to deliver. Concurrently, regional single-use plastic bans, like Victoria’s 2023 mandate, pressed them to find compliant alternatives.

In response, Eco-Brew initiated extensive trials of various heat-resistant eco-friendly straws. After rigorous testing, they opted to switch to advanced sugarcane bagasse straws, certified compostable and proven to withstand temperatures up to 100°C (212°F) without losing structural integrity. This strategic pivot yielded remarkable results: within six months of the full transition, customer satisfaction scores related to their hot beverage experience increased by a notable 15%. Furthermore, their waste audit compliance improved significantly, demonstrating a tangible positive impact on their environmental footprint and regulatory standing. The successful integration of these straws allowed Eco-Brew to meet strict environmental standards while simultaneously elevating their brand perception among a rapidly growing segment of eco-conscious consumers.

ROI Beyond Compliance: Brand Image and Customer Loyalty

The return on investment for adopting superior heat-resistant eco-friendly straws extends far beyond simply avoiding fines. This strategic move can significantly bolster a company’s bottom line through:

- Enhanced Brand Perception: In today’s market, consumers are increasingly prioritizing sustainability. Adopting certified heat-resistant eco-friendly straws demonstrates a genuine commitment to environmental stewardship, improving brand perception and resonating deeply with eco-conscious customers. This positive image translates directly into increased sales and market share.

- Operational Efficiency & Cost Savings: While initial procurement costs for advanced materials might be higher, the reduction in “soggy straw” complaints leads to fewer refunds or remakes, enhancing operational efficiency. Furthermore, by adopting certified compostable options, businesses can reduce waste disposal costs associated with non-recyclable plastics, especially in regions with escalating landfill taxes or stricter waste segregation mandates.

- Strengthened Customer Loyalty: A superior customer experience, free from the frustration of a disintegrating straw, fosters repeat business and positive word-of-mouth. This enhances customer loyalty, transforming a potentially negative interaction into a moment that reinforces brand quality and care.

- Alignment with Corporate Sustainability Goals: Investing in these solutions directly contributes to a company’s broader corporate sustainability goals and Environmental, Social, and Governance (ESG) targets. This alignment is increasingly important for attracting ethically-minded investors, employees, and business partners. Procurement managers are keenly aware of the need for bulk supply, consistent quality, competitive pricing, and reliable supply chains for these crucial components. As consumer perception continues to drive demand for higher quality, durable eco-friendly options, the market for products like eco-friendly cocktail straws for B2B is also growing.

**Adopting heat-resistant eco-friendly straws boosts brand image, operational efficiency, and customer loyalty for hospitality businesses.**

VII. Future Outlook for Eco-Friendly Straw Innovations

The innovation pipeline for eco-friendly straws, particularly those designed for hot beverages, is robust and rapidly advancing. The drive for truly sustainable and high-performing alternatives will continue to shape material science and manufacturing processes over the next 5-10 years.

Ongoing Research and Development (R&D) is intensely focused on further improving the thermal stability and cost-effectiveness of biopolymers. Scientists are exploring novel blends and polymerization techniques to push the boundaries of heat resistance for biodegradable materials. For instance, academic research continues to investigate methods to improve the hydrophobicity and mechanical strength of natural materials, aiming to overcome the limitations of early-generation solutions.

New materials are constantly emerging, promising enhanced functionality and broader applicability. Examples include those refined from edible starch combined with lignin and citric acid, which are showing promise for superior hydrostability and strength. The future will also see greater integration of circular economy principles, with an emphasis on creating solutions that are not just compostable but can be recycled back into new products or designed for durable reuse, minimizing resource depletion.

Crucially,collaboration across material science, manufacturing, and the food service sectorswill accelerate innovation. This interdisciplinary approach is essential to translate laboratory breakthroughs into scalable, commercially viable products. The demand for materials that maintain stability and taste neutrality in hot liquids for extended periods remains a primary goal. The next decade will likely witness a diversification of heat-resistant eco-friendly straw options, addressing specific operational needs and catering to an increasingly discerning market that prioritizes both performance and planet. For a deeper dive into material science advancements and their environmental implications, consider exploring relevant scientific papers, such as those found on reputable academic platforms likeResearchGate.**Future innovations promise even more durable, cost-effective, and circular heat-resistant eco-friendly straw solutions.**

Conclusion: Elevate Your Brand with Superior Heat-Resistant Eco-Friendly Straws

The transition to heat-resistant eco-friendly straws is unequivocally more than a mere regulatory necessity; it represents a profound strategic opportunity for forward-thinking businesses. By proactively investing in certified, high-performance sustainable straw solutions, your organization can significantly reduce its environmental footprint, ensure seamless compliance with an increasingly stringent regulatory landscape, and crucially, deliver an unparalleled customer experience that mitigates the long-standing “soggy straw” frustration. This proactive approach transforms a potential compliance challenge into a distinct competitive advantage, positioning your brand as an industry leader in sustainability and customer satisfaction.

Act now to future-proof your procurement strategy; secure your market leadership and elevate your brand’s reputation. Request a compliance-ready sample pack today to explore the next generation of heat-resistant eco-friendly straws and transform your hot beverage service, recognizing that the future of beverage service is undeniablyeco-friendly drinking straws.

Häufig gestellte Fragen

Why are traditional paper straws unsuitable for hot beverages in hospitality?

Traditional paper straws quickly become soggy and disintegrate in hot liquids, compromising the customer experience and leading to dissatisfaction in cafes, hotels, and restaurants.

What are the key benefits of switching to heat-resistant eco-friendly straws?

Benefits include enhanced customer satisfaction, compliance with plastic bans, improved brand image, reduced waste disposal costs, and alignment with corporate sustainability goals.

Are heat-resistant eco-friendly straws truly compostable or biodegradable?

Many advanced options like SC-PLA and sugarcane (bagasse) straws are certified compostable (e.g., BPI, TÜV Austria), ensuring they break down safely in commercial composting facilities.

How do new bioplastics like SC-PLA and PHA perform in hot beverages?

SC-PLA straws remain stable even in boiling water, while PHA straws offer durability comparable to traditional plastic across various temperatures, resisting sogginess effectively.

What certifications should procurement managers look for when sourcing these straws?

Look for certifications like BPI (ASTM D6400), TÜV Austria (EN 13432), and ABA (AS4736) for compostability, and ensure FDA approval for food safety and absence of harmful chemicals like PFAS.