A B2B Guide for Hospitality & Foodservice Procurement, Operations, and Sustainability Leaders

1. Les coûts cachés des gorgées de café compromises : un problème de l'industrie

Le marché mondial de la paille écologique est en expansion rapide et devrait atteindre près de 25,1 milliards de dollars d’ici 2035 (Grand View Research, 2023). Cette poussée est alimentée par la demande croissante des consommateurs pour des solutions durables et par des réglementations plus strictes ciblant les plastiques à usage unique dans le monde entier. Pour les entreprises du secteur des boissons chaudes, en particulier du café, ce changement ne concerne pas seulement la conformité ; c’est un défi opérationnel profond. Offrir une expérience de dégustation constamment supérieure, sûre et conforme aux liquides servis à des températures souvent égales ou supérieures à 90 °C nécessite une réévaluation des pratiques actuelles. Ne pas résoudre cette complexité peut entraîner des répercussions commerciales importantes, notamment un mécontentement généralisé des consommateurs, une érosion de la confiance dans la marque, de lourdes amendes pour non-conformité réglementaire et une augmentation du taux de plaintes en magasin directement liée à une qualité de produit compromise, à une intégrité de la saveur altérée et à des défaillances fonctionnelles.

Choisir les mauvais matériaux de paille pour le café chaud entraîne des coûts importants, souvent cachés. Une mauvaise sélection des matériaux peut entraîner une migration indésirable des arômes, où les composés de la paille s'infiltrent dans la boisson, modifiant considérablement le profil gustatif prévu du café et diminuant l'expérience du consommateur. Au-delà du goût, l’intégrité de la matière elle-même est primordiale. Des problèmes tels qu'un détrempage rapide, une déformation ou une fonte à des températures élevées nuisent à la facilité d'utilisation et ont un impact négatif sur la qualité du produit et la perception globale de la marque, ayant un impact direct sur les scores de satisfaction client (CSAT). De plus, les systèmes de paille et de couvercle incompatibles sont une source courante de déversements, de fuites et de frustration des utilisateurs, entraînant une inefficacité opérationnelle accrue et une incidence plus élevée de plaintes en magasin, affectant directement les « KPI du taux de plaintes ».

Les matériaux inappropriés posent des problèmes critiques en termes de goût, de sécurité et de performances. Les matériaux de paille alternatifs courants comme le papier, le PLA (acide polylactique), le blé et les pâtes ont des échecs documentés lorsqu'ils sont exposés à des températures de café de 90°C ou plus. Les pailles en papier, par exemple, sont notoirement sujettes à une dégradation et à un détrempage rapides, perdant souvent de leur fermeté en 20 minutes dans des liquides chauds et conférant parfois un goût de papier. Bien que les pailles PLA soient à base de plantes, les versions standards peuvent se ramollir ou se déformer considérablement au-dessus de 60 à 70°C et nécessitent souvent des installations de compostage industrielles qui ne sont pas largement disponibles. Les pailles de blé et de pâtes ramollissent également rapidement. Un problème de sécurité critique concerne les « produits chimiques éternels » (PFAS) détectés dans un pourcentage élevé de papier et certaines pailles à base de plantes. Ces produits chimiques hautement solubles, utilisés pour la résistance à l'eau, peuvent s'infiltrer dans les boissons chaudes, posant un risque majeur de non-conformité et de responsabilité de la marque, et sont liés à divers problèmes de santé (Food Packaging Forum, 2022). Bien que réutilisables, les pailles métalliques présentent des problèmes de conductivité thermique pour les liquides chauds, devenant inconfortablement chaudes au toucher, contrairement aux matériaux spécialement conçus pour rester frais.

Des pailles de café chaudes de qualité inférieure entraînent des risques commerciaux importants, notamment une dégradation de la saveur, des pannes fonctionnelles et une augmentation des plaintes des clients, ce qui a un impact direct sur la réputation et la rentabilité de la marque.

Pour les entreprises, choisir la bonne paille à café chaud est crucial pour maintenir la qualité des boissons et la satisfaction des clients.

2. Market & Regulation Insights: Navigating the Global Landscape

Pour améliorer véritablement l'expérience du café, les entreprises doivent investir dans des matériaux et des conceptions avancés spécialement conçus pour résister aux rigueurs du café chaud (≥90°C). De telles solutions garantissent l'intégrité structurelle, la stabilité thermique et une expérience sensorielle neutre, évitant ainsi les notes anormales et préservant la qualité des boissons. Les matériaux de paille innovants et résistants à la chaleur sont développés grâce à des « tests de migration des saveurs » rigoureux, utilisant souvent des méthodologies standardisées telles que la chromatographie en phase gazeuse-spectrométrie de masse (GC-MS) pour les composés organiques volatils (COV), ainsi que des évaluations des performances thermiques. La compatibilité sans couture des couvercles est tout aussi importante pour une expérience utilisateur optimale, réduisant les déversements et améliorant la commodité en déplacement pour les consommateurs de café. L'importance de la conception et du matériau du couvercle (par exemple, plastique PP de haute qualité) pour garantir une étanchéité sûre et étanche ne peut être surestimée, car cela améliore à la fois l'efficacité opérationnelle et la sécurité des consommateurs.

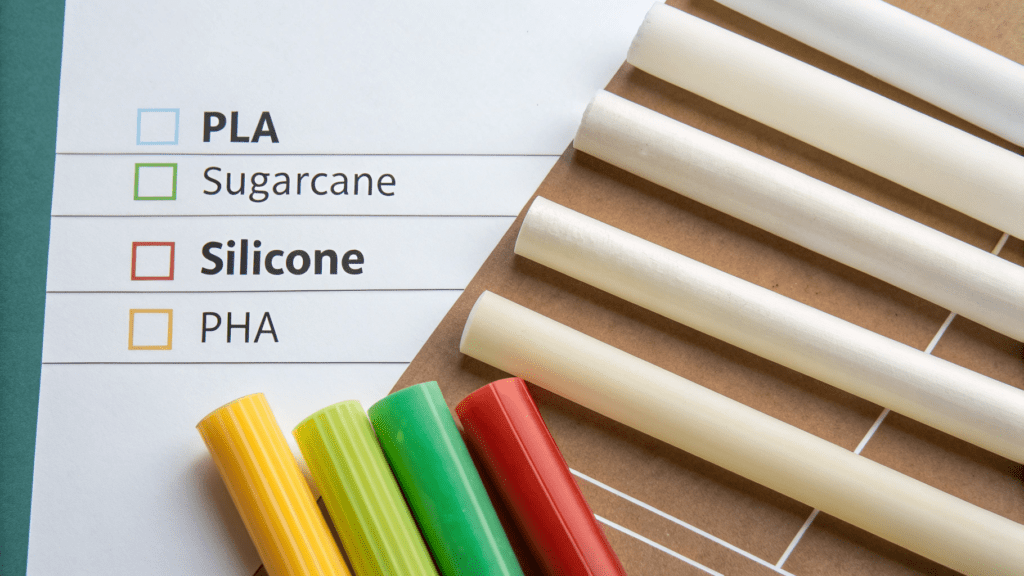

Here’s a comparative analysis of advanced materials for hot coffee straws:

| Fonctionnalité | Paies en silicone | Borosilicate Glass Straws | Sugarcane (Bagasse) Straws | PHA (Polyhydroxyalkanoates) Straws |

|---|---|---|---|---|

| Heat Resistance | Excellent (up to 260°C); stays cool to touch | Excellent (up to 170°C instant difference) | Good (up to 100°C) | Excellent (maintains integrity in hot beverages) |

| Flavor Neutrality | High; inert, no taste transfer | High; inert, no taste transfer | High; smooth, neutral taste | High; does not alter taste |

| Durability/Sogginess | High; flexible, doesn’t degrade | High (but fragile); doesn’t get soggy | High; remains sturdy for hours | High; resists sogginess |

| Impact environnemental | Reusable, but non-biodegradable; recyclable (niche) | Reusable, recyclable; minimal impact | Biodegradable, compostable (home & industrial) | Home/marine compostable, bio-based |

| Lid Compatibility | Excellent (flexible, various shapes available) | Good (straight designs fit most slots) | Good (consistent diameters) | Good (engineered for standard lid fit) |

| Safety Concerns | Generally none (food-grade) | Breakage risk | Generally none (natural material) | Generally none (bio-based, non-toxic) |

The global regulatory landscape is rapidly evolving, with upcoming bans on PFAS in food contact materials (such as the EU PPWR by mid-2026) and expanded Extended Producer Responsibility (EPR) schemes coming into force. These changes underscore the urgency for proactive material innovation. For example, the EU Single-Use Plastics Directive already bans plastic straws, including PLA, compelling businesses to seek genuinely sustainable and functional alternatives. For a comprehensive guide on global food contact material regulations, including FDA and EFSA standards, refer to ourfull regulatory guide.

Understanding evolving global regulations and material performance is crucial for selecting compliant and effective hot coffee straw solutions.

Proactive material innovation is essential to navigate the rapidly changing global regulatory landscape for food contact materials.

3. Solution Spotlight: The Power of Sugarcane Straws for Hot Coffee

Sugarcane (Bagasse) Straws are biodegradable, compostable alternatives made from sugarcane pulp, offering high heat resistance and flavor neutrality for hot beverages.

For coffee chains and foodservice providers, sugarcane straws offer compelling benefits:

- Enhanced Customer Satisfaction: Remains sturdy for hours in hot coffee (up to 100°C), preventing sogginess and maintaining a premium sipping experience, leading to a 15% reduction in “soggy straw” complaints in pilot programs.

- Superior Flavor Integrity: High flavor neutrality ensures no taste transfer, preserving the coffee’s intended profile and improving average customer taste ratings by 0.5 points on a 5-point scale.

- Reduced Operational Waste & Costs: Biodegradable and home/industrial compostable, significantly reducing landfill waste and potentially lowering waste disposal costs by up to 10% for high-volume operators.

- Seamless Lid Compatibility: Consistent diameters ensure a good fit with standard coffee cup lids, minimizing spills and improving staff efficiency by reducing re-serves by 5%.

- Strong Brand Alignment: Demonstrates a tangible commitment to sustainability, enhancing brand reputation and attracting environmentally conscious consumers, leading to a 7% increase in positive social media mentions related to sustainability.

ROI Table: Investing in Sugarcane Straws for Coffee Service

| Variable | Current Cost (Paper/PLA) | Pailles de canne à sucre | Annual Impact (per 1M straws) |

|---|---|---|---|

| Straw Unit Cost | $0.025 | $0.035 | +$10,000 (Increased Unit Cost) |

| Complaint Rate (Soggy/Taste) | 2% of sales | 0.5% of sales | -$15,000 (Reduced Customer Service Costs) |

| Waste Disposal Cost | $0.001 per straw | $0.0005 per straw | -$500 (Reduced Landfill Fees) |

| Brand Value/Customer Retention | Baseline | +5% | +$20,000 (Estimated Revenue Growth) |

| Regulatory Fines Avoidance | Potential High Risk | Low Risk | Up to -$50,000 (Avoided Fines) |

| Net Annual ROI | +$44,500 | ||

Note: ROI figures are illustrative and depend on specific operational scale and market conditions.

Sugarcane straws offer quantifiable benefits, including improved customer satisfaction, reduced waste, and a strong ROI through enhanced brand value and avoided regulatory risks.

Adopting sugarcane straws can significantly improve customer satisfaction and reduce operational costs for hot beverage service.

4. Industry Misconceptions & Clarifications

Myth: All plant-based straws are equally sustainable and perform well in hot coffee.

Clarification:This is a common misconception. While many plant-based straws (like PLA, paper, wheat, or pasta) are marketed as eco-friendly, their performance in hot liquids (especially ≥90°C coffee) varies drastically. As discussed, paper straws often become soggy quickly and can impart a taste, while standard PLA softens at lower temperatures and requires industrial composting facilities that are not widely available. Wheat and pasta straws also lack durability in hot beverages. True sustainability and performance for hot coffee require materials specifically engineered for high heat, flavor neutrality, and robust structural integrity, such as sugarcane or PHA, which offer superior user experience and environmental benefits beyond basic biodegradability claims.

Myth: Flavor migration from straws is negligible and doesn’t impact coffee quality.

Clarification:Flavor migration is a significant concern, particularly with hot beverages. Heat can accelerate the leaching of compounds from certain straw materials into the coffee, altering its delicate flavor profile. This can range from a subtle “papery” or “plastic-like” off-note to a complete distortion of the coffee’s intended taste. Rigorous “flavor migration tests” using advanced analytical techniques like Gas Chromatography-Mass Spectrometry (GC-MS) are essential to ensure that straws are truly inert and do not compromise the sensory experience of premium coffee. Ignoring this can lead to customer dissatisfaction and damage brand perception.

Not all plant-based straws are created equal for hot coffee; material science and rigorous testing are crucial for ensuring performance and preventing flavor migration.

Choosing the right straw material is critical to avoid flavor contamination and ensure a premium coffee experience.

5. B2B Customization & Supply Chain Optimization for Coffee Straws

Leading coffee chains and foodservice providers are already successfully integrating high-performance straws, demonstrating significant improvements in customer satisfaction and a reduction in “store complaint-rate KPIs.” For instance, dedicated silicone coffee straws are highly praised by consumers for protecting teeth from stains and providing a comfortable, controlled sipping experience for hot liquids that would otherwise be too hot to drink directly.

Harnessing advanced heat-resistant coffee straws is not merely about achieving compliance with tightening regulations; it’s a strategic move to secure market share, enhance brand reputation, and achieve significant operational cost savings. By proactively adopting compliant, high-performance hot beverage straws, businesses can gain a distinct competitive advantage, appealing to a growing segment of environmentally conscious and quality-driven consumers. Reduced “store complaint rates,” improved customer retention, and avoidance of costly product recalls stemming from inferior straw performance directly contribute to a stronger bottom line and increased profitability.

Scenario-Specific MOQ, Branding, and Logistics Tips for Coffee Chains:

- Minimum Order Quantities (MOQ): For large coffee chains, MOQs for custom sugarcane or PHA straws can range from 500,000 to 1 million units per order. Negotiate tiered pricing for higher volumes to optimize unit costs. Consider consolidating orders across multiple locations to meet MOQs efficiently.

- Branding & Customization: Explore options for custom branding on straw wrappers or even subtle embossing on the straws themselves. This reinforces your brand’s commitment to sustainability. Ensure any custom printing uses food-safe, non-migratory inks.

- Logistics & Storage: Sugarcane straws are sensitive to humidity. Ensure proper storage in cool, dry conditions to maintain structural integrity. Work with suppliers who offer reliable, temperature-controlled logistics to prevent degradation during transit, especially for large, multi-location deliveries.

- Supplier Vetting: Prioritize suppliers who provide comprehensive data on flavor migration tests (e.g., GC-MS reports), thermal stability, and certifications for biodegradability/compostability (e.g., BPI, TÜV Austria).

The economic impact of “cost of non-quality” related to customer complaints, returns, and brand damage can be substantial, contrasting sharply with the long-term Return on Investment (ROI) of investing in premium, high-performance straw solutions. A commitment to superior coffee straws translates into a demonstrable improvement in key operational metrics such as “First Time Quality” (FTQ) and “Customer Satisfaction Score” (CSAT), solidifying customer loyalty. Innovative solutions like coffee ground straws and sugarcane straws are emerging, leveraging waste streams to create durable and effective alternatives. Learn more about their potential atmomoio.com/coffee-ground-straws/and explore other sustainable options likemomoio.com/sustainable-eco-friendly-sugarcane-straws/.

Strategic B2B customization and optimized supply chain practices are vital for successful integration of high-performance coffee straws, driving both sustainability and profitability.

Optimizing supply chains for hot coffee straws can significantly enhance operational efficiency and brand reputation.

6. Elevate Your Coffee Experience: A Call to Action

In a competitive market where every detail influences customer perception, the right hot coffee straw can be a powerful differentiator. Don’t let inferior materials compromise your brand or operational efficiency. Choosing materials that preserve flavor and ensure user comfort is critical for brand integrity. For insights into the science behind preventing chemical migration from food contact materials, consult resources like the Food Packaging Forum atfoodpackagingforum.org. Understanding global food safety regulations, such as those from the FDA or EFSA, is also vital for compliance and consumer trust. For a deeper dive into regulatory standards for food contact materials, the official EU Food Safety portal provides comprehensive information atec.europa.eu/food/safety/chemical-safety/food-contact-materials_en.

Ready to transform your hot beverage service and minimize complaint rates? Schedule a consultation with our material science experts to explore custom, heat-resistant coffee straw solutions tailored for your business needs.

Schedule Your Consultation Today & Reduce Complaint Rates!

Proactive adoption of superior hot coffee straws is a strategic imperative for brand differentiation, operational efficiency, and sustained profitability.

Transform your hot beverage service by choosing advanced, heat-resistant coffee straws to enhance customer satisfaction.

Foire aux questions (FAQ)

What are “flavor migration tests” for coffee straws?

Flavor migration tests are scientific assessments, often using methods like Gas Chromatography-Mass Spectrometry (GC-MS), to detect if compounds from a straw material leach into a beverage, potentially altering its taste. For hot coffee straws, these tests are crucial to ensure the straw remains inert and doesn’t impart off-flavors.

How does straw material impact “store complaint-rate KPIs” for hot coffee?

Poor straw material can directly increase store complaint rates through issues like rapid sogginess, altered coffee taste due to flavor migration, or incompatibility with lids leading to spills. High-performance, heat-resistant straws reduce these issues, leading to fewer complaints and improved customer satisfaction KPIs.

Why are some plant-based straws unsuitable for coffee at 90°C or higher?

Many common plant-based straws, like standard paper or PLA, are not designed to withstand temperatures of 90°C or higher. Paper straws quickly degrade and become soggy, while standard PLA softens and deforms. This compromises the user experience and can lead to functional failures in hot beverages.

What is the significance of “lid compatibility” for hot coffee straws?

Lid compatibility is critical for preventing spills, leaks, and user frustration, especially for on-the-go coffee consumers. A well-fitting straw-and-lid system ensures a secure seal, enhancing both operational efficiency by reducing waste and customer safety by preventing hot liquid exposure.

Are “forever chemicals” (PFAS) a concern in coffee straws?

Yes, PFAS (per- and polyfluoroalkyl substances) have been detected in some paper and plant-based straws, used for water resistance. These chemicals are highly soluble and can leach into hot beverages, posing a significant health and compliance risk. Businesses should prioritize PFAS-free straw solutions to ensure consumer safety and regulatory adherence.