Tablo kann se yon tabl jetab ak zanmitay anviwònman an ki fèt ak bagas nan kaka mouye oswa tablo kaka ak modle lè l sèvi avèk yon machin tabli moule.

Non pwodwi: Tablo kann

Non altènatif: tabl kaka kann

Yon dyagram koule pwosesis yo itilize pou ilistre sekans etap yo ak entèrelasyon ki genyen ant aktivite nan yon pwosesis.

Pwosesis fabrikasyon an enplike pulping, peze, koupe, ak anbalaj.

Plis pase 80% nan tablo kaka a kreye nan kaka banbou, ki se yon melanj de kaka kann ak kaka banbou nan pwopòsyon kondisyon yo ki nan lòd soti nan kaka kann, kaka banbou, elatriye. Pwopòsyon kaka kann ak kaka banbou yo itilize varye selon kondisyon kliyan yo. Pulping machin yo itilize pou melanje kaka a nan konbinezon diferan nan kaka kann ak kaka banbou, ki tranpe pou 5 minit. Apre yo fin tranpe, machin nan vire sou kaka, ak likid la pulping Lè sa a, mete nan pisin nan kaka pou dilution. Pandan dilution, yon ajan lwil oliv-prèv ak yon ajan dlo-prèv yo ajoute nan pisin nan kaka, ak ajitatè a melanje kaka a pandan tout pwosesis la dilution. Se kaka a dilye ponpe nan pisin nan rezèv kaka epi brase kontinyèlman, sa ki lakòz yon metòd pulping.

The forming machine of the disposable environmental protection paper mold automatic production line receives pulp through the pulp supply pipe, where vacuum suction and filtration remove the water from the pulp to keep the fibers in the pulp adsorbed on the forming screen to create a wet embryo. The wet embryo is squeezed out of water and dried under a temperature of 230 and a pressure of 15 tons to create semi-finished products.

The semi-finished products are taken to the trimming post after shaping, where the trim is cut away using a cutting knife.

The inspectors inspect the products after they have been cut to ensure they meet the customer’s standards. Those that do not meet the customer’s requirements are picked out and discarded. The products are then disinfected using UV disinfection machines.

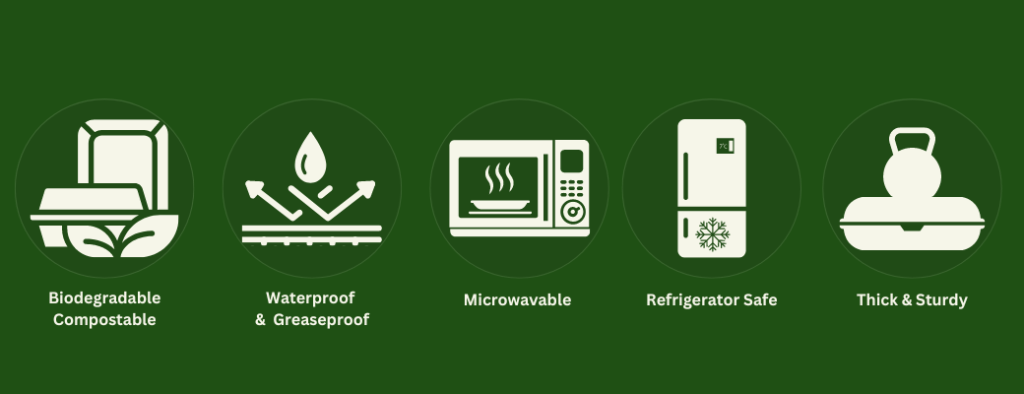

Sugar cane pulp tableware products are characterized by the following features.

1) Waste paper pulp or renewable straw fibers such as wheat, reed, straw, bamboo, sugar cane, palm, and so on, which are inexpensive and widely available, can be used without any wood at all.

2) No wastewater is produced in the production process, and no external discharge occurs.

3) waterproof and oil-proof products can be produced using

4) The products can be -18 °C frozen, refrigerated, microwave heated, or baked at 220 °C.

5) The products when decomposed in nature, can be broken down completely in 45-90 days, resulting in no waste or pollution. Organic matter is the primary component of degradation.

6) The product is non-toxic and harmless, and it is safe and secure

We can supply bagasse bowls, plates, trays, knives, forks and spoons, lunch boxes, cups, etc. Feel free to contact us for the latest product information.