Старший специалист по контент-стратегии в области устойчивого развития B2B

The global push for sustainability has transformed the operational landscape for B2B enterprises. With heightened environmental awareness and an increasingly complex web of regulations, businesses are under immense pressure to adopt greener practices. At the forefront of this shift is the growing demand for compostable materials, particularly those certified by theBiodegradable Products Institute (BPI). BPI certification serves as a vital assurance for environmental claims, but for procurement managers, operations directors, sustainability officers, and supply chain executives in the hospitality and foodservice industries, understanding the precise breakdown timelines and conditions for BPI-certified materials is paramount. Ignoring this crucial detail can lead to compliance risks, operational inefficiencies, and missed opportunities in a rapidly evolving market.

Consider the commercial implications: the global compostable packaging market, valued at USD 55.53 billion in 2024, is projected to reach USD 89.85 billion by 2032, demonstrating a robust Compound Annual Growth Rate (CAGR) of 6.20% from 2025 to 2032 (Source:Grand View Research, 2024). This surge reflects not just a trend but a fundamental recalibration of supply chains toward circularity. Businesses that clearly grasp the mechanics of BPI compostability are better positioned to meet this demand, mitigate waste disposal costs, and enhance their brand reputation. This guide provides essential, data-backed insights for B2B decision-makers on the composting performance of BPI-certified materials, helping you navigate this strategic imperative with confidence.

Understanding BPI compostable material breakdown is crucial for hospitality and foodservice businesses to ensure compliance and seize market opportunities.

Decoding BPI Compostable Material Breakdown Times for B2B Operations

BPI-certified compostable materials are not merely “biodegradable” in a vague sense; they are meticulously engineered to break down under specific, controlled conditions found in industrial composting facilities. This distinction is critical for B2B operations, as it directly impacts waste management strategies and environmental claims. The certification process mandates adherence to rigorous American Society for Testing and Materials (ASTM) standards, primarily ASTM D6400 and ASTM D6868.

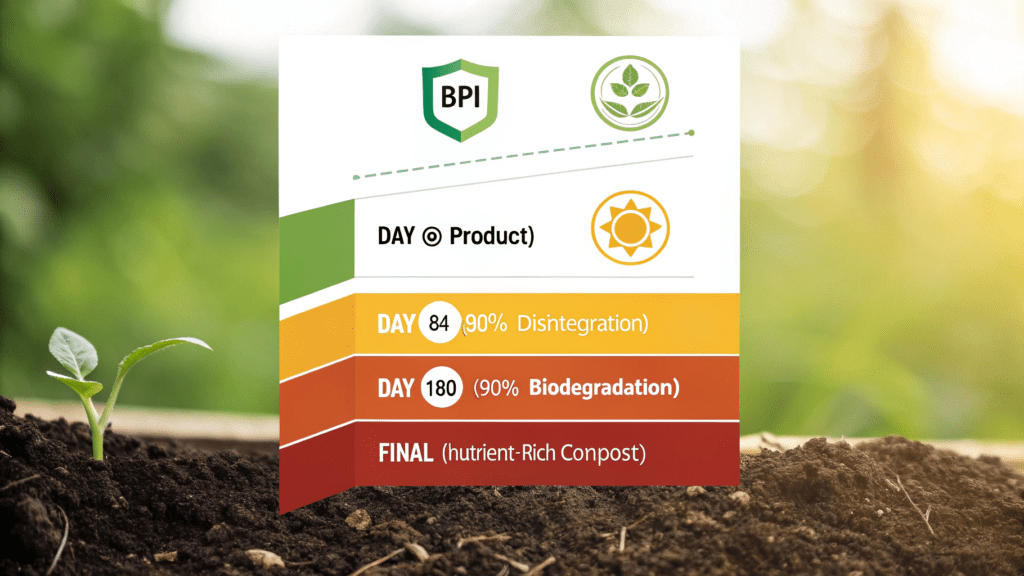

These standards stipulate clear performance benchmarks. For physical disintegration, BPI-certified products are required to break down into small fragments (less than 2mm) within84 days (12 weeks)when subjected to industrial composting conditions. This ensures that the material becomes indistinguishable from compost. Beyond physical disintegration, full biodegradation—the conversion of organic carbon into carbon dioxide, water, inorganic compounds, and biomass—must occur to at least 90% within180 days (6 months). Crucially, this process must leave no toxic residues or heavy metals, ensuring the resulting compost is safe and beneficial for soil.

Adhering to ASTM Standards: D6400 and D6868 Requirements

The ASTM D6400 standard specifically addresses compostable plastics, while ASTM D6868 applies to composite materials, such as those combining bioplastics with paper or fiber. Both standards are foundational to BPI certification, dictating how products must perform in an industrial composting environment. They mandate a minimum of 90% biodegradation of organic carbon into CO2 within the 180-day timeframe, demonstrating that the material is truly consumed by microorganisms. Furthermore, the 90% physical disintegration requirement by 84 days ensures the material does not remain as problematic fragments in the finished compost. A key aspect of these standards is the prohibition of toxic residues or heavy metals remaining post-composting, guaranteeing the integrity and safety of the final compost product. This rigorous testing and certification process helps businesses avoid misleading “greenwashing” claims and ensures genuine environmental impact.

The Critical Role of Industrial Composting Facilities

It is vital for B2B stakeholders to understand that BPI-certified products are explicitly designed for industrial composting facilities, not backyard compost piles or general landfills. Industrial facilities provide the optimal conditions—high heat (typically 150-160°F), controlled moisture levels, and consistent aeration—that are essential for accelerating microbial activity and efficient decomposition. These controlled environments ensure that BPI-certified materials break down according to their intended timelines.

Without access to such facilities, even BPI-certified products may not decompose as intended, potentially ending up in landfills where they can decompose anaerobically and produce methane, a potent greenhouse gas. The actual time required for products to break down can also vary in practice, ranging from 30 to 190 days depending on facility-specific factors like management practices and the specific material composition and thickness. This variability underscores the importance of a robust composting infrastructure, a significant challenge in many regions across North America and Europe.

BPI-certified materials break down within 84-180 days under industrial composting conditions, crucial for effective B2B waste management.

The Strategic Imperative: BPI Certified Compostable Materials and Compliance

Adopting BPI-certified materials is more than an environmental gesture; it’s a strategic business imperative that ensures alignment with emerging sustainability mandates and safeguards brand reputation. The BPI certification mark validates environmental claims, providing third-party verification that products meet stringent scientific standards. This is particularly crucial as regulatory bodies and consumers increasingly scrutinize corporate sustainability initiatives, especially within the hospitality and foodservice sectors where single-use items are prevalent.

Beyond breakdown performance, BPI certification also includes critical safeguards against harmful chemicals. Since January 1, 2020, BPI has required all certified items to be below 100 parts per million (ppm) total fluorine, effectively ensuring no intentionally added PFAS (per- and polyfluoroalkyl substances) are present. This proactive measure mitigates legal and reputational risks associated with persistent chemicals. It’s also important to reiterate that “compostable” (with its defined breakdown time and conditions) differs significantly from the general and often undefined term “biodegradable,” providing a much higher standard of environmental responsibility. To delve deeper into these distinctions, explore our guide onBPI Compostable vs. Biodegradable: Sustainability Guide.

Navigating Regulatory Landscapes and Certification

The regulatory landscape around compostable materials is rapidly evolving, posing both challenges and opportunities for businesses. In the U.S., the Department of Agriculture’s (USDA) National Organic Program (NOP) is currently debating whether to include bioplastics in certified organic compost, a decision that will profoundly impact the composting industry. Similarly, Extended Producer Responsibility (EPR) laws are gaining traction in North America, with several Canadian provinces and four U.S. states having passed such legislation. BPI actively advocates for these EPR funds to specifically support the expansion of composting infrastructure and public education, rather than being diverted to other waste management streams.

Furthermore, consumer confusion regarding proper disposal remains a significant hurdle. Studies show that nearly a third of surveyed consumers mistakenly place compostable packaging in recycling bins (Source:Resource Recycling, 2023). To combat this, BPI, in collaboration with the U.S. Composting Council (USCC), is working to develop principles for clear, standardized labeling, including the prominent display of the BPI mark. Clear labeling is crucial for minimizing contamination and ensuring compostable items reach their intended end-of-life pathways, especially in high-volume environments like hotels and cafeterias.

BPI certification ensures compliance and mitigates risks, crucial for hospitality and foodservice navigating evolving sustainability regulations.

Quantifying Value: Operational Impact of BPI Compostable Solutions

Integrating BPI-certified compostable materials into your supply chain offers tangible operational benefits that extend beyond environmental compliance. A primary advantage is the reduction in landfill waste, which directly translates into lower disposal costs for businesses. As landfill tipping fees continue to rise and regulatory pressures mount, diverting waste from landfills becomes an increasingly attractive economic proposition for hotels, restaurants, and catering services.

However, the path is not without challenges. Contamination from non-compostable materials remains a significant hurdle for composting facilities, costing some up to 17% of their total operating expenses in contaminant removal (Source:US Composting Council, 2023). This issue highlights the critical need for effective collection systems and consumer education within hospitality and foodservice settings. Moreover, the insufficient industrial composting infrastructure in many regions presents logistical hurdles, requiring businesses to carefully assess local capabilities when implementing compostable solutions. Despite these challenges, adopting BPI-certified solutions significantly enhances a company’s corporate social responsibility (CSR) profile, strengthens brand image, and improves market positioning in an increasingly eco-conscious economy.

| Особенность | Операционное влияние B2B | Примечание о соответствии | Потенциал рентабельности инвестиций |

|---|---|---|---|

| BPI Certification | Ensures proper end-of-life disposal in industrial settings; simplifies waste stream management for hospitality. | Meets ASTM D6400/D6868; avoids harmful residues, supporting organic compost standards. | Improved brand image; supports sustainability goals, attracting eco-conscious customers. |

| Material Choice (e.g., PLA) | Versatile for various packaging and foodservice applications (e.g., rigid containers, films). | Must achieve 90% disintegration (84 days) and 90% biodegradation (180 days). | Accesses growing market segments (Food & Beverage: 48.7% of global market by 2025); broad applicability. |

| Industrial Composting | Requires specific collection and processing logistics; optimizes decomposition process. | BPI-certified products depend on these controlled conditions for effective breakdown. | Diversion from landfill saves disposal costs; reduces methane emissions, contributing to carbon reduction targets. |

| PFAS-Free Commitment | Ensures product safety and purity; avoids potential regulatory scrutiny and liability. | BPI requires less than 100ppm total fluorine since January 2020. | Mitigates legal and reputational risks; builds consumer trust and differentiates offerings. |

Real-World Performance: Insights from the Composting Consortium Study

The effectiveness of BPI-certified materials in real-world industrial composting environments has been rigorously validated. A groundbreaking large-scale field study, conducted in April 2024 by the Composting Consortium (an initiative of Closed Loop Partners) in North America, provides compelling evidence. This study rigorously tested over 23,000 units of certified food-contact compostable packaging across 10 diverse U.S. composting facilities, representing various operational parameters.

The findings were highly encouraging: compostable plastic packaging achieved an impressive 98% disintegration on average, significantly exceeding the industry threshold of 90%. Similarly, compostable fiber packaging demonstrated 83% disintegration on average, meeting established industry benchmarks. This study confirms that when BPI-certified packaging is processed in facilities meeting reasonable operational parameters, it breaks down successfully, underscoring the reliability of the BPI standard in practical applications. This real-world validation should instill confidence in B2B decision-makers in hospitality and foodservice considering a transition to compostable solutions. To understand more about managing this transition effectively, consider reviewing ourB2B Playbook for Sustainable Waste Management.

BPI-certified solutions offer tangible operational benefits, including reduced landfill costs and enhanced CSR profile.

Propelling Forward: The Market Outlook for BPI Compostable Materials

The trajectory for BPI compostable materials is one of significant expansion, fueled by increasing consumer demand, regulatory drivers, and continuous innovation. The global compostable packaging market is projected to reach USD 89.85 billion by 2032, exhibiting a robust 6.20% Compound Annual Growth Rate (CAGR) from 2025-2032. This growth is a clear indicator that businesses prioritizing compostable solutions are aligning with a dominant market trend.

Polylactic Acid (PLA), derived from renewable agricultural sources like corn starch and sugarcane, is poised to remain a leading material, forecast to hold a substantial 36.4% market share by 2025 in the compostable plastic packaging segment. Its versatility in applications, from rigid containers to flexible films, positions it as a go-to material for various industries, especially the food and beverage sector, which is expected to lead end-use demand with a 48.7% share by 2025. Key industry leaders like Amcor, Mondi Group, NatureWorks, and Eco-Products are actively investing in and expanding their compostable offerings, signaling a broader industry commitment.

Driving Adoption: Innovation and Infrastructure Investment

The escalating consumer demand for sustainable products is actively fueling the shift towards a circular bioeconomy model, where materials are designed to be reused, recycled, or composted. Material science advances are continuously yielding more robust and versatile compostable solutions. Beyond established materials like PLA, innovative new options are emerging, including Polyhydroxyalkanoates (PHA) – polymers produced by microbial fermentation – and even mycelium-based packaging derived from mushroom root structures, offering eco-friendly alternatives to traditional plastic foams. These innovations are expanding the functional capabilities of compostable materials, matching those of conventional plastics in many applications relevant to hospitality and foodservice.

Technological integration, such as the application of Artificial Intelligence (AI) and Machine Learning (ML) in certification processes, is set to enhance transparency and efficiency in verifying biodegradability. Crucially, meeting the growing demand and policy goals hinges on significant investment in composting infrastructure. Initiatives like the US Composting Infrastructure Coalition (USCIC) are working to establish widespread composting capabilities, promoting legislation and grants to fund the necessary expansion. This commitment to infrastructure development is paramount for B2B enterprises to fully realize the environmental and economic benefits of BPI-certified materials. For hospitality businesses looking to leverage BPI certification for their sustainability goals, our guide onBPI Compostable Certification & Hospitality Sustainabilityoffers valuable insights.

The compostable materials market is expanding, driven by innovation and crucial infrastructure investments for B2B adoption.

Competitive Advantage & Business Case

For B2B decision-makers in hospitality and foodservice, embracing BPI-certified compostable materials translates into a compelling competitive advantage and a robust business case. Beyond the direct environmental benefits, there are quantifiable gains. By reducing landfill waste, companies can achieve significant cost savings on disposal fees, which can amount to a substantial portion of operational expenses. Furthermore, compliance with evolving regulations, such as the EU Single-Use Plastics Directive and emerging US EPR laws, mitigates the risk of fines and legal challenges, preserving brand equity.

The market share opportunity is substantial: with the global compostable packaging market poised for significant growth, early adopters gain a first-mover advantage. Companies that demonstrably commit to BPI-certified solutions can attract the growing segment of eco-conscious consumers and B2B partners, enhancing brand value and fostering deeper customer loyalty. This strategic pivot can also lead to improved supplier relationships with innovative material providers and the potential for new revenue streams through sustainable product lines. The shift to compostable packaging is not just about reducing environmental footprint; it’s about positioning your business for future market leadership and resilience in a sustainability-driven economy.

Adopting BPI-certified materials offers a competitive edge, reducing costs, ensuring compliance, and enhancing brand value.

Заключение

BPI-certified compostable materials offer a vital, scientifically backed pathway to achieving sustainable operations. Understanding their precise breakdown timelines—physical disintegration within 84 days and full biodegradation within 180 days under industrial composting conditions—is foundational for effective B2B waste management and sustainability strategies. Businesses that prioritize BPI certification gain not only compliance assurance and mitigated environmental risks but also a clear competitive advantage in a rapidly expanding eco-conscious market.

Transform your supply chain for a sustainable future. Partner with certified BPI compostable material suppliers to achieve your environmental goals and enhance operational efficiency today.

Embrace BPI-certified compostable materials to achieve sustainability goals and gain a competitive edge in the B2B market.

Contact Us for Sustainable Solutions

Часто задаваемые вопросы (FAQ)

Q: How do BPI-certified materials benefit my hotel’s waste management costs?

A: By diverting BPI-certified compostable items from landfills to industrial composting facilities, hotels can significantly reduce landfill tipping fees. This also helps avoid potential fines associated with increasing waste disposal regulations, leading to direct cost savings and improved operational efficiency.

Q: What are the key differences between “compostable” and “biodegradable” for foodservice packaging?

A: “Compostable” (especially BPI-certified) means a product will break down into natural elements in a specific timeframe (84-180 days) under industrial composting conditions, leaving no toxic residue. “Biodegradable” is a broader, less regulated term that doesn’t guarantee breakdown within a specific timeframe or environment, often leading to confusion and potential greenwashing.

Q: How can a large-scale catering operation ensure proper disposal of BPI-certified materials?

A: Catering operations should implement clear, color-coded waste bins for compostables, provide staff training on proper sorting, and partner with local industrial composting facilities. Clear labeling on packaging (e.g., the BPI logo) also helps minimize contamination from guests.

Q: Are BPI-certified products safe for food contact in restaurants?

A: Yes, BPI certification includes strict requirements for product safety. Since January 2020, BPI has mandated that all certified items contain less than 100 ppm total fluorine, effectively ensuring no intentionally added PFAS chemicals are present, making them safe for food contact.

Q: What is the role of industrial composting facilities in the breakdown of BPI materials?

A: Industrial composting facilities provide the high heat, controlled moisture, and aeration necessary for BPI-certified materials to break down efficiently within the specified 84-180 day timeframe. Without these controlled conditions, the materials may not decompose as intended.