Introduction: Navigating Sustainable Packaging for Operational Excellence

In an era defined by heightened environmental awareness and evolving regulatory landscapes, sustainable packaging choices are no longer optional for modern businesses; they are critical for operational excellence and long-term viability. As procurement managers, operations directors, sustainability officers, and supply chain executives navigate complex decisions, understanding robust certification standards becomes paramount. The Biodegradable Products Institute (BPI) certification stands as a leading guide in North America for verifying compostable products. This guide will explore BPI’s rigorous standards, its unwavering commitment to compost safety, and how embracing BPI-certified materials can empower your organization to meet escalating sustainability targets, mitigate compliance risks, and enhance brand reputation.

The urgency to adopt truly sustainable practices is underscored by the escalating global plastic waste crisis and tightening regulations. Businesses face increasing pressure to divert waste from landfills, which not only contributes to greenhouse gas emissions but also incurs significant operational costs. Choosing the right compostable solutions, validated by reputable third-party certifications like BPI, ensures that your efforts translate into genuine environmental impact and commercial advantage, rather than falling prey to greenwashing claims.

Embracing BPI-certified materials is crucial for hospitality and foodservice to meet sustainability targets and enhance brand reputation.

Understanding “BPI Compost Safe”: The Gold Standard in North America

Established in 1999, the Biodegradable Products Institute (BPI) is a non-profit, multi-stakeholder organization comprising representatives from government, industry, and academia. BPI serves as North America’s leading third-party certifier for compostable products and packaging, playing a crucial role in promoting the use and recovery of biodegradable materials through composting. Its primary mission is to verify that products will biodegrade safely and effectively in managed compost facilities, promoting the scalable diversion of organic waste from landfills to valuable composting operations.

The BPI Certification Mark is recognized as a definitive symbol of compostability within the value chain, ensuring that products bearing this label have been independently tested and verified. This robust verification process addresses past skepticism about products making unsubstantiated “biodegradable” claims, providing confidence to consumers, businesses, and composting facilities alike. To learn more about how BPI certification drives sustainable practices in the hospitality sector, explore our insights onBPI Compostable Certification & Hospitality Sustainability.

Adherence to Compostable Packaging Standards: ASTM D6400 and D6868

BPI-certified products are rigorously tested to comply with specific ASTM (American Society for Testing and Materials) technical standards, which are foundational to their certification. These include:

- ASTM D6400: This standard specifically addresses the “Standard Specification for Labeling of Plastics Designed to Be Aerobically Composted in Municipal or Industrial Facilities,” primarily applied to bioplastics.

- ASTM D6868: This standard focuses on the “Standard Specification for Labeling of End Items That Incorporate Plastics and Polymers as Coatings or Additives with Paper and Other Substrates Designed to Be Aerobically Composted in Municipal or Industrial Facilities.”

These standards ensure that BPI-certified products fully break down into carbon dioxide, water, inorganic compounds, and biomass. The decomposition must occur efficiently within industrial composting conditions, typically within 90 to 180 days. Crucially, certification ensures that no harmful residues or heavy metals are left behind, safeguarding the quality and safety of the resulting compost for agricultural or landscaping applications. These scientifically backed standards are developed through a five-year process involving 15 organizations under the ASTM Institute for Standards and Research (ISR), correlating laboratory tests with real disposal systems. (Source:BPIworld.org)

BPI certification ensures products meet rigorous ASTM standards for safe, complete breakdown in industrial composting.

The Scientific Rigor of BPI Compost Safety: Beyond Claims

Achieving BPI certification requires comprehensive independent testing that goes beyond mere claims of biodegradability. Products must demonstrate performance across three critical criteria: biodegradation, disintegration, and ecotoxicity.

For biodegradation, products must achieve 90% absolute biodegradation or 90% relative to a suitable positive reference substrate within six months in a compost pile. This ensures that the material is converted into carbon dioxide by organisms at an acceptable rate. Physical disintegration is equally vital; products must physically break apart and blend into the compost, with 90% completion within 84 days (12 weeks), preventing items from clogging screening equipment in composting facilities. Finally, the resulting compost is subjected to ecotoxicity tests to ensure it supports safe plant growth, confirming no harmful substances or residues are released that could negatively impact soil health or the environment.

Eliminating Harmful Chemicals: The PFAS Regulation and BPI Certification

A cornerstone of BPI’s commitment to safety is its proactive stance on harmful chemicals, particularly per- and polyfluoroalkyl substances (PFAS). As of January 1, 2020, BPI implemented a strict prohibition against intentionally added PFAS in any certified products. This critical standard prevents “forever chemicals,” known for their environmental persistence and potential health impacts, from contaminating compost streams.

To uphold this, all products seeking BPI certification must provide a test report showing less than 100 ppm total organic fluorine, along with a signed statement from the manufacturer confirming no intentionally added fluorinated chemicals. Furthermore, BPI mandates full formulation disclosure for certification, including all ingredients, even those below 0.1% by dry weight, along with supplier information, CAS numbers, and Safety Data Sheets (SDS) for non-BPI certified ingredients. This level of transparency and rigorous testing ensures that BPI-certified compost is truly safe and beneficial for soil.

BPI certification rigorously tests for biodegradation, disintegration, and ecotoxicity, prohibiting harmful PFAS chemicals.

BPI Compost Safe vs. Misleading Labels: A Strategic Comparison

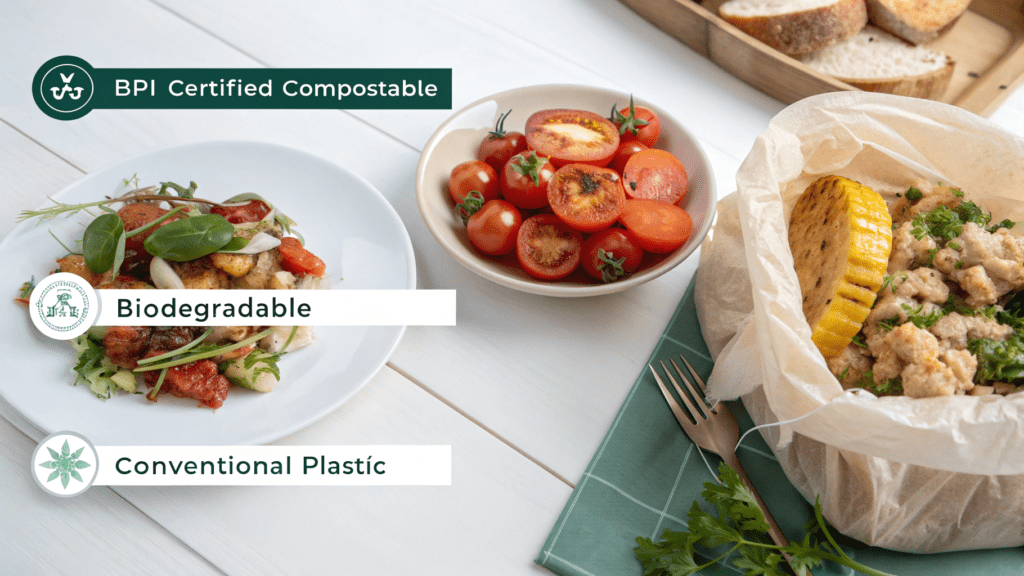

Navigating the myriad of “eco-friendly” labels can be challenging for B2B decision-makers. Many terms like “biodegradable” or “plant-based” lack verifiable standards, leading to widespread confusion and potential contamination of organic waste streams. BPI certification stands apart by offering a robust, third-party verified standard for industrial compostability.

The following table highlights the critical differences between BPI Certified Compostable products and other common categories, underscoring their operational impact, compliance implications, and ROI potential for businesses:

| Característica | Impacto operativo B2B | Nota de cumplimiento | Potencial de retorno de la inversión |

|---|---|---|---|

| Compostable certificado BPI | Streamlines organic waste diversion; accepted by most industrial composters, reducing sorting burden. | Meets ASTM D6400/D6868; PFAS-free since 2020; transparent, third-party verification. | Reduced contamination costs (approx. 17% of composter operating costs); enhanced brand reputation, attracting eco-conscious customers; supports ESG goals and avoids plastic bans. |

| Non-Certified “Biodegradable” | High risk of rejection by composters due to lack of verified breakdown; leads to landfilling or incineration. | No verified standard; terms often lack scientific rigor for composting conditions or toxic residue testing. | Negative impact on sustainability initiatives; potential for reputational damage and consumer distrust due to greenwashing. |

| Conventional Plastic | Familiar disposal routes (landfill/recycling where available); limited organic waste diversion capabilities. | Not designed for composting; contributes to plastic pollution; increasing regulatory pressure (e.g., single-use plastic bans) and long-term environmental liability. | Lower upfront material costs, but increasing regulatory fines, potential legal liabilities, and damage to corporate social responsibility (CSR) standing. |

Choosing BPI-certified products significantly reduces the risk of contaminating organic waste streams, a major cost driver for composting facilities. Some composters report that approximately 17% of their total operating expenses are spent on removing non-compostable contaminants, highlighting the direct financial benefit of verified compostable solutions.

BPI certification offers clear operational, compliance, and ROI advantages over misleading “biodegradable” labels.

Real-World Impact: Demonstrating BPI Compost Safe Performance

While laboratory testing provides the scientific foundation, BPI also emphasizes real-world performance. In early 2021, BPI launched its “Field Validation Program” to track how certified products perform under actual commercial composting conditions. This initiative bridges the gap between lab compliance and practical results, building greater trust among composting facilities.

To date, the program has compiled publicly available data indicating that over 1,000 BPI-Certified products have successfully passed field tests, with some achieving complete breakdown in as little as 49 days. This robust data reinforces that BPI-certified products not only meet stringent lab standards but also deliver on their promise in commercial composting environments.

Mini Case Study: Leading Foodservice Provider’s Sustainable Transition

A major North American foodservice operator recognized the growing imperative for sustainable waste management and sought to enhance its environmental stewardship. Faced with the challenge of diverting significant volumes of food scraps and associated packaging from landfills, the operator transitioned its entire disposable packaging portfolio to exclusively BPI-certified items.

By meticulously sourcing and implementing BPI-certified compostable straws, cups, and containers, the foodservice provider significantly mitigated contamination risks within its organic waste streams. This strategic shift streamlined their waste management processes, leading to a notable boost in waste diversion rates and a cleaner, more valuable compost output. The operator’s commitment to BPI standards demonstrated that verified compostable solutions facilitate not only operational efficiency but also genuine environmental stewardship, enhancing their brand image among increasingly eco-conscious consumers. For a deeper dive into how BPI-certified compostable straws contribute to hospitality sustainability, read our article onBPI Certified Compostable Straws: Hospitality & Sustainability.

BPI-certified products demonstrate proven real-world performance, enabling significant waste diversion for foodservice operators.

Market Landscape and Future Outlook for BPI Compost Safe Solutions

The market for compostable solutions is experiencing robust growth, driven by a confluence of consumer demand, evolving regulatory frameworks, and ambitious corporate ESG policies. The global compostable plastic packaging material market, for instance, is projected to reachUSD 3.5 billion by 2035, expanding at a compound annual growth rate (CAGR) of5.2%. Within this burgeoning market, Polylactic acid (PLA) is anticipated to remain the leading material, holding an estimated36.4% market share in 2025due to its versatility and alignment with sustainability initiatives. The food and beverage industry continues to be the largest sector for compostable packaging, expected to account for a substantial48.7% of the global market by 2025.

Addressing Consumer Confusion and Enhancing Industrial Composting Acceptance

Despite this promising market trajectory, a significant challenge remains: consumer confusion. A joint study conducted by Closed Loop Partners’ Composting Consortium and BPI in December 2022, based on a survey of 2,765 U.S. respondents, revealed concerning misconceptions. The study found that49% of consumers confuse the terms “biodegradable” and “compostable,”often believing them to be interchangeable. Furthermore, up to50% of respondents incorrectly believed that packaging labeled “made from plants” was inherently compostable, highlighting the prevalence of misleading claims in the market. This confusion directly contributes to improper disposal, with nearly one-third of respondents indicating they would incorrectly place compostable packaging in a recycling bin, leading to contamination of recycling streams or landfills. (Source:Closed Loop Partners)

To counter this, BPI released its 2020 Labeling Guidelines, aiming to standardize identification and reduce contamination. Consistent, clear on-product labeling is crucial for helping end-users, consumers, and composters easily distinguish truly compostable items, thereby diverting food scraps and creating cleaner organics streams. Ongoing education and clear certification marks like BPI’s are vital to ensuring that investment in compostable products translates into real environmental benefits and streamlined waste management operations.

The compostable market is growing, but clear BPI labeling is vital to combat consumer confusion and ensure proper disposal.

Competitive Advantage & Business Case: Quantifying the Value of BPI Certification

For B2B decision-makers, embracing BPI-certified compostable solutions offers a compelling business case that extends far beyond environmental goodwill. Quantifiable benefits include:

- Ahorro de costos: By ensuring materials properly break down, BPI certification dramatically reduces contamination within organic waste streams. As noted, contamination can account for approximately 17% of composter operating costs, a significant burden that can be mitigated by verifiable compostable inputs. This translates to lower processing fees, reduced rejection rates for organic loads, and more efficient waste management for your enterprise.

- Mitigación de riesgos: The regulatory landscape is rapidly shifting, with increasing bans on single-use plastics and mandates for organic waste diversion in regions across the US and EU. Adopting BPI-certified products proactively aligns your operations with these evolving regulations, safeguarding against potential fines, legal liabilities, and supply chain disruptions.

- Brand Value Uplift and Market Share Opportunity: Demonstrating a genuine commitment to sustainability through verifiable certifications like BPI enhances your brand reputation. This resonates strongly with increasingly eco-conscious consumers and B2B partners, opening doors to new market segments and bolstering customer loyalty. It directly supports your organization’s Environmental, Social, and Governance (ESG) goals, providing a tangible narrative for corporate responsibility reports and investor relations. By being an early adopter and clear leader in truly compostable solutions, you can carve out a competitive advantage and capture a larger share of a market that values authenticity and proven environmental performance.

BPI certification offers quantifiable benefits, including cost savings, risk mitigation, and enhanced brand value for B2B operations.

Conclusion: Empowering Sustainable Operations with BPI Certification

BPI certification is the definitive assurance for “BPI compost safe” products, ensuring complete, non-toxic breakdown in industrial composting facilities. For procurement managers, operations directors, and sustainability officers, BPI certification is critical for achieving genuine sustainability and waste diversion goals. It mitigates risks of contamination, supports circular economy initiatives, and aligns with growing regulatory pressures, offering a clear path to operational efficiency and environmental leadership.

Actúe ahora:Verify your packaging portfolio, partner with BPI-certified suppliers, and drive your organization’s transition to truly compostable solutions. Access the BPI online product database today to ensure compliance, maximize your environmental impact, and position your business at the forefront of the sustainable economy.

BPI certification empowers hospitality and foodservice leaders to achieve sustainability, mitigate risks, and lead in the circular economy.

Preguntas frecuentes (preguntas frecuentes)

What does BPI certification mean for my hospitality business?

BPI certification ensures that disposable products like cups, cutlery, and food containers will safely and completely break down in commercial composting facilities, preventing contamination of organic waste streams and supporting your sustainability goals.

How does BPI certification help reduce operational costs for foodservice providers?

By using BPI-certified products, foodservice providers can significantly reduce contamination in their organic waste, leading to lower waste disposal fees, fewer rejected loads by composters, and more efficient waste management operations.

Are BPI-certified products truly free of harmful chemicals like PFAS?

Yes, as of January 1, 2020, BPI prohibits intentionally added PFAS in all certified products. This ensures that BPI-certified compost is safe and free from “forever chemicals” that could harm soil health.

Can BPI-certified products be composted in a home compost pile?

BPI certification is specifically for industrial composting facilities, which operate at higher temperatures and with controlled conditions necessary for complete breakdown. Home composting conditions vary greatly and may not be sufficient.

How can I verify if a product is BPI certified?

Look for the BPI Certification Mark on the product or packaging. You can also verify a product’s certification status by searching its name or certification number on the official BPI online product database.