For procurement managers, operations directors, sustainability officers, and supply chain executives in hospitality & foodservice.

For procurement managers, operations directors, sustainability officers, and supply chain executives, high-quality compost isn’t just an agricultural input—it’s a critical component of sustainable operations, soil health, and regulatory compliance. Subpar compost, or material that has “gone bad,” can lead to significant operational disruptions, compliance risks, and financial losses, impacting everything from landscaping projects and agricultural yields to corporate sustainability targets.

The stakes are high. If ignored, the use of compromised compost can result in crop damage that reduces yields by as much as 80-90%, necessitate costly operational re-work, and introduce legal liabilities related to environmental regulations. This guide provides a comprehensive framework forhow to know if compost is bad, empowering B2B decision-makers to identify issues, ensure quality, and mitigate risks in their composting supply chains, thereby safeguarding both ecological integrity and commercial viability.Ensuring compost quality is vital for B2B sustainability and financial stability.

The Hidden Costs of Bad Compost: Why Quality Matters for B2B Operations

The ripple effect of poor compost quality extends far beyond initial appearance, imposing substantial hidden costs across B2B operations. These financial and reputational burdens underscore the strategic imperative of rigorous compost quality control.

- Phytotoxicity and Yield Reduction: A primary concern is phytotoxicity, where incompletely cured compost contains organic acids, ammonia, or other compounds toxic to plants. If not properly stabilized, these phytotoxic elements can severely stunt plant growth, reduce crop vitality, and lead to dramatic yield losses, potentially impacting crop yields by up to 80-90%. This directly translates to significant agricultural revenue losses and increased costs for replanting or remediation.

- Contamination and Operational Overhead: Compromised compost frequently introduces impurities, including physical contaminants like plastics, glass shards, or ceramics, as well as chemical residues such as persistent herbicides, pesticides, or “forever chemicals” (PFAS). The presence of these non-compostable or harmful materials necessitates increased operational costs for their removal, proper disposal, and potential equipment damage, adding unforeseen expenses to the supply chain.

- Regulatory Non-Compliance and Reputational Damage: Non-compliant compost poses severe regulatory risks, especially concerning permissible levels of heavy metals and pathogens (e.g., fecal coliforms, Salmonella). Regulatory bodies, such as the EPA (40 CFR Part 503 for biosolids) and various state and international standards, enforce strict limits. Failing to meet these standards can result in hefty fines, legal action, market access restrictions, and severe damage to a company’s brand reputation and public trust, particularly in sectors with strong sustainability mandates.

- Inconsistent Quality and Project Delays: Fluctuating compost quality, often due to inconsistent feedstock inputs, improper C:N ratios, or inadequate temperature and moisture control during production, disrupts project timelines and requires additional resource allocation for testing, remediation, or sourcing alternative materials. This unpredictability can significantly inflate project costs and compromise operational efficiency.

Poor compost quality incurs significant financial, operational, and reputational costs for businesses.

How to Know if Compost is Bad: Key Indicators for Procurement & Quality Control

Identifying poor compost quality begins with a systematic assessment, moving from immediate sensory and visual cues to more advanced analytical metrics.

Sensory Signals: Foul Odors and Unpleasant Textures Indicate Poor Compost Quality Standards

A healthy, mature compost pile should possess a distinct and pleasant aroma, reminiscent of fresh forest soil after a rain. Any deviation from this earthy scent signals a potential problem, particularly a lack of oxygen (anaerobic conditions).

- Foul Odors:

- Rotten Egg or Sulfurous Odors: These are clear indicators of anaerobic conditions, often resulting from excessive moisture, over-compaction, or too many food scraps shredded into small pieces. Such smells signify the presence of hydrogen sulfide and other undesirable byproducts. As confirmed by the University of California Agriculture and Natural Resources, this putrid scent means the pile needs aeration.

- Ammonia or Fishy Smells: These suggest an imbalance, typically an excess of nitrogen (from “green” materials like grass clippings or manure) and insufficient carbon. This imbalance can lead to nitrogen loss through volatilization, as noted by LSU AgCenter.

- Sour, Vinegar, or Rancid Butter Smells: These are further indicators of anaerobic conditions, often leading to “sour compost” that can be detrimental to plant health.

- Intensely Moldy or Musty Smell: While some white fuzz (mycelium) is normal, an overpowering moldy or musty smell can signal issues.

- Chemical Smell: A distinct chemical smell, such as gasoline or creosote, is a serious red flag, indicating contamination from pesticides, herbicides, or other industrial chemicals, rendering the compost unusable.

- Unpleasant Textures:

- Slimy or Matted Textures: These textures point to excessive moisture and poor aeration, creating an oxygen-deprived environment that hinders proper decomposition and can foster harmful pathogens. Compost should feel moist, like a wrung-out sponge, forming a ball when squeezed but not dripping water, according to Eartheasy.com.

- Dry or Ashy Feel: Conversely, if the compost feels overly dry or dusty, it lacks sufficient moisture for microbial activity, slowing down or halting the decomposition process.

Foul odors and unpleasant textures are immediate red flags for bad compost.

Visual Cues: Unrecognized Materials and Contamination Raise Red Flags for Compost Quality Standards

Visual inspection provides immediate clues about the compost’s maturity and purity.

- Unrecognized Materials: Finished compost should be dark brown or black, uniform in texture, and resemble rich soil. If recognizable food scraps, large pieces of plant material, or undecomposed woody materials are still visible after a reasonable composting period, it signifies incomplete decomposition. This suggests the compost may still contain viable weed seeds or pathogens. As Gardening Know How states, completed compost should be dark and uniform.

- Physical Contaminants: The unambiguous presence of physical contaminants like plastics, glass shards, ceramics, or metals indicates poor source separation and inadequate quality control during the composting process. These foreign materials reduce compost utility, can damage application equipment, and, if not removed, can introduce microplastics or other harmful substances into the soil. Guidelines from entities like the British Columbia government often specify strict limits for foreign matter.

- Excessive Mold or Slime: While beneficial fungi (white mycelium) are common in healthy compost, extensive visible white, green, or black mold, or significant slime, points to excessive moisture and insufficient aeration, creating conditions favorable for harmful pathogens.

- Pale Color: Mature compost should be dark brown to black. A pale color, rather than a rich, dark hue, often indicates incomplete decomposition or an imbalance in the carbon-to-nitrogen ratio, signifying that the composting process has stalled or is not optimized.

Visual inspection reveals incomplete decomposition or harmful contaminants in compost.

Beyond the Obvious: Advanced Metrics to Assess Compost Quality and Maturity

While sensory and visual cues are useful initial indicators, B2B decision-makers require more precise, data-backed metrics to thoroughly assess compost quality and ensure it meets stringent performance and regulatory requirements.

Temperature Dynamics: Critical for Pathogen Control and Compost Maturity Indicators

Temperature is a direct indicator of microbial activity and the efficacy of the composting process, especially concerning pathogen destruction.

- Optimal Heat Generation: An actively decomposing compost pile should generate heat, ideally maintaining internal temperatures between 120-150°F (49-66°C). This thermophilic phase is crucial for effectively breaking down organic materials and, critically, for killing weed seeds and harmful pathogens.

- Regulatory Thresholds: Regulatory bodies enforce specific temperature thresholds to ensure pathogen reduction. The USDA National Organic Program (NOP), for instance, mandates temperatures of 55-71°C for a minimum of three days in in-vessel or aerated static piles. For windrow composting, the requirement is 55-71°C maintained for at least 15 days, with the pile turned a minimum of five times during this period to ensure uniform heating. This ensures the compost is safe for unrestricted use.

- Inactive Piles: A consistently cold and inactive pile might be too small (an ideal size is typically at least 3x3x3 ft for efficient heat retention), too dry, or lacking sufficient nitrogen to fuel microbial activity, as highlighted by Broome County, NY.

- Overheating Risks: While beneficial, excessive heat can be problematic. Temperatures consistently exceeding 160°F (71°C) can begin to kill off beneficial microorganisms, effectively sterilizing the pile and halting further decomposition. In extreme cases, especially with large industrial piles, overheating can even cause spontaneous combustion, as noted by Eartheasy.com.

Temperature indicates microbial activity, crucial for pathogen control and compost maturity.

Chemical and Biological Signatures: Understanding C:N Ratio, pH, and Phytotoxicity Testing

For a comprehensive assessment, chemical and biological analyses provide insights into the compost’s stability, nutrient content, and potential harm to plants.

- Carbon-to-Nitrogen (C:N) Ratio: This fundamental ratio dictates the efficiency of microbial decomposition. The optimal C:N ratio for compost feedstock typically ranges between 25:1 and 40:1, which then stabilizes to a range of 10-20:1 in mature compost. As Cornell University explains, maintaining this balance ensures effective decomposition and prevents issues like nitrogen lock-up in the soil. A high C:N ratio in finished compost might lead to nitrogen immobilization when applied, stunting plant growth.

- pH Levels: Compost pH is a critical indicator of maturity and suitability for agricultural use. Ideally, mature compost should have a pH between 6 and 8.5. Values consistently below 6 can signal incompletely cured, phytotoxic compost due to the presence of unstable organic acids, according to Utah State University Extension.

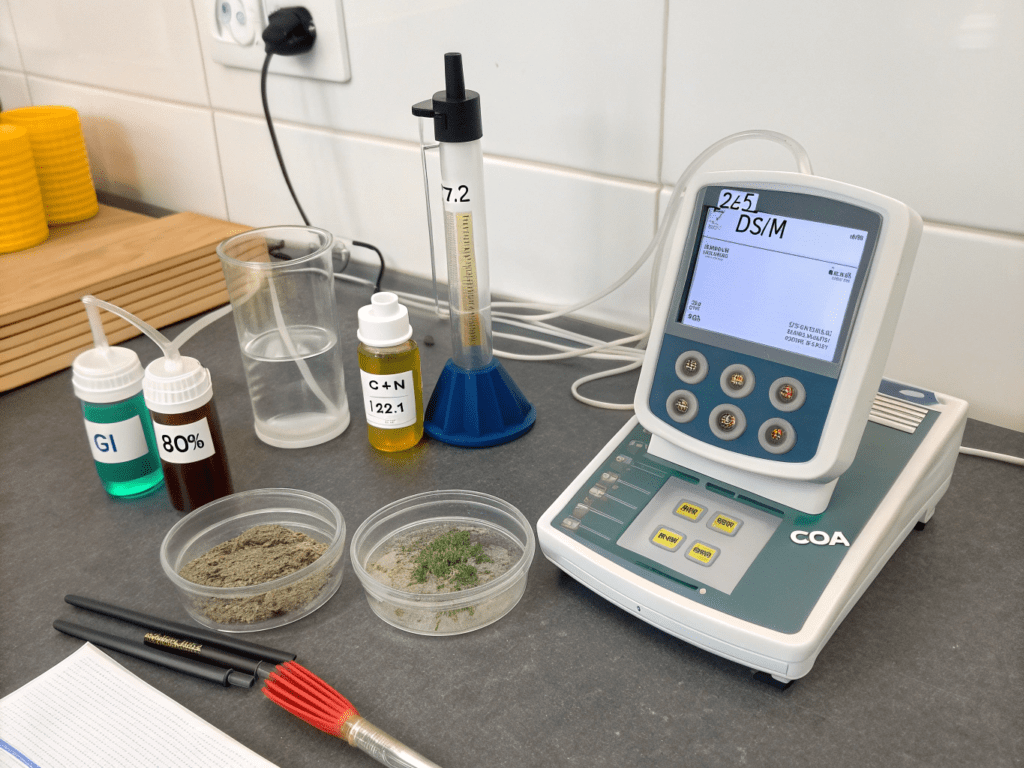

- Phytotoxicity Assessment: This is a direct measure of a compost’s potential to harm plant growth. Phytotoxicity is commonly assessed via germination tests, where seeds are grown in compost or its extract. A Germination Index (GI) of less than 80% indicates potential toxicity to plants, with values below 50% suggesting a high level of phytotoxicity, as detailed in research published by MDPI. Root elongation is often considered more sensitive to toxins than seed germination.

- Soluble Salt Content (Electrical Conductivity – EC): Electrical Conductivity (EC) measures the concentration of soluble salts, which can be detrimental to plant growth, particularly in sensitive seedlings or when compost is used at high rates. Compost with an EC exceeding 8 dS/M (decisiemens per meter) may require restricted use or dilution to avoid harming plants, as advised by Utah State University Extension.

Chemical and biological tests reveal compost stability, nutrient content, and plant safety.

The Compliance and ROI Nexus: Why Investing in High-Quality Compost Matters

High-quality compost is not merely an expense but a strategic investment that delivers tangible B2B benefits, driving compliance, operational efficiency, enhanced brand value, and a significant return on investment.

| Särdrag | B2B operationell påverkan | Efterlevnadsanteckning | ROI -potential |

|---|---|---|---|

| Consistent Maturity | Reduces crop damage and operational re-work; ensures reliable performance. | Meets NOP requirements for pathogen and weed seed reduction (55°C+ for specified durations). | Enhanced crop yields (e.g., 15% increase), reduced chemical fertilizer costs (e.g., 10% reduction), minimized re-application. |

| Low Contamination | Minimizes equipment damage, reduces disposal costs, improves product purity. | Adheres to strict foreign matter limits (e.g., CCME guidelines) and chemical residue thresholds. | Lower operational waste, improved public and stakeholder perception, enhanced brand value. |

| Optimal C:N Ratio | Ensures stable nutrient release, preventing nitrogen lock-up or loss. | Supports nutrient management plans and aligns with sustainable soil health regulations. | Increased soil fertility, reduced need for supplemental synthetic nitrogen, improved plant vigor. |

| Verified Phytotoxicity | Guarantees plant health and project success; prevents costly plant replacement. | Achieves Germination Index (GI) > 80% for plant safety, adhering to industry best practices. | Minimized plant mortality, accelerated landscaping project completion, reduced input costs. |

Mini Case Study: Agrify Solutions’ Turnaround with Certified Compost

Agrify Solutions, a large-scale agricultural enterprise with extensive landholdings, faced consistent issues with reduced yields and crop damage. Their problem stemmed from sourcing inconsistent compost that frequently contained high levels of phytotoxic compounds and persistent herbicides, directly impacting their quarterly projections and long-term sustainability goals.

In Q3 2023, after multiple crop failures that threatened their market position, Agrify pivoted their procurement strategy. They initiated partnerships with suppliers certified by the US Composting Council’s Seal of Testing Assurance (STA) program. This strategic shift ensured that all incoming compost met stringent third-party validated standards for maturity (with a Germination Index consistently above 80%), heavy metals, and the complete absence of chemical residues.

Within six months, Agrify reported a remarkable 15% increase in crop vitality and a 10% reduction in chemical fertilizer application costs across their operations. This translated to a projected annual ROI of 2.5 times their initial investment in premium, certified compost. Beyond the financial gains, this shift significantly bolstered their corporate sustainability reporting, allowing Agrify to prominently feature their commitment to responsible sourcing and soil health, aligning with growing consumer and regulatory demand for organically-produced goods and sustainable agricultural practices.High-quality compost drives compliance, operational efficiency, and significant ROI for businesses.

Navigating the Compost Landscape: Addressing Common Challenges in B2B Sourcing

Despite the clear benefits of high-quality compost, the industry faces several pervasive challenges that B2B buyers must navigate to secure reliable and compliant supply. Understanding these hurdles is critical for effective procurement and risk management.

- Contamination: Contamination remains a significant barrier to compost quality. The presence of non-compostable materials like plastics, glass, and heavy metals (regulated by standards such as EPA 40 CFR Part 503 for biosolids) drastically reduces compost quality and significantly increases processing and disposal costs. The visual similarity between compostable and conventional plastics further complicates source separation, a challenge that even materials designed to be compostable, such as certified compostable straw materials for the foodservice industry, aim to mitigate. The infiltration of microplastics, organic pollutants, and chemical residues like PFAS is a growing concern, often not routinely monitored due to prohibitive costs.

- Variable Compost Quality: A key pain point for B2B buyers is the inherent variability in compost quality. This inconsistency often stems from inconsistent feedstock inputs and operational hurdles such as inadequate moisture management, imbalanced carbon-to-nitrogen ratios, and fluctuating temperature control. This directly impacts the reliability and performance of compost for large-scale applications, leading to unpredictable results and requiring additional pre-application analysis.

- Complex Regulatory Compliance: Large-scale composting facilities face a complex and stringent regulatory landscape, particularly regarding emissions, leachate management, and ensuring the elimination of pathogens and weed seeds. Expert opinions from organizations like the US Composting Council highlight that navigating these rules requires significant resources and specialized expertise, impacting the cost and availability of compliant compost.

- Limited Market Acceptance and Awareness: Despite its benefits, the market acceptance for finished compost can sometimes be limited. This is often due to a perceived inconsistency in quality among potential agricultural and landscaping users, coupled with a general lack of awareness regarding the diverse applications and advantages of high-quality compost as a soil amendment. As noted by Closed Loop Partners, addressing these perception gaps is crucial for market expansion.

- Infrastructure Gaps: Significant infrastructure gaps persist, particularly for the development of large-scale facilities capable of processing substantial volumes of organic waste and for the long-distance transport of food waste. These limitations create logistical and cost inefficiencies in the supply chain, hindering the ability to scale composting efforts to meet widespread B2B demand.

B2B compost sourcing faces challenges like contamination, variable quality, and regulatory complexities.

Future-Proofing Your Operations: Leveraging Advancements in Compost Quality Assessment

The composting industry is rapidly evolving, driven by sustainability mandates, technological innovation, and a global push towards circular economy models. B2B decision-makers can future-proof their operations by aligning with these advancements, ensuring access to superior compost products and practices.

- Market Growth and Demand: The global compost market is projected to reach an estimated $13 billion by 2030, growing at a robust Compound Annual Growth Rate (CAGR) of 7% from 2023. This surge is fueled by increasing demand for organic products, a deeper understanding of the environmental disadvantages of chemical fertilizers, and a growing emphasis on sustainable waste management, as projected by Lucintel. This expanding market signifies increasing opportunities for B2B procurement of high-quality compost.

- Technological Integration for Precision Composting: The future of composting lies in precision. Widespread integration of IoT, AI, and automation is enabling sophisticated monitoring and optimization of composting parameters such as temperature, moisture, and oxygen. As detailed by CEBA Solutions, these advancements are leading to more consistent compost quality, reduced operational costs, and faster decomposition cycles, making industrial composting more efficient and scalable.

- Rigorous Testing and Certification Programs: To meet the demand for reliable, high-performance compost, the industry is increasingly adopting rigorous testing and certification protocols. Programs like the US Composting Council’s Seal of Testing Assurance (STA) provide crucial third-party validation for critical parameters including nutrient content, pH, maturity, and pathogen safety. This trend extends to specialized certifications, such as BPI compostable certification for hospitality and foodservice industries, ensuring that compostable products properly break down in industrial facilities, thereby contributing to higher quality end-compost.

- Real-Time Monitoring and Comprehensive Analysis: Advancements are allowing for real-time monitoring and more comprehensive parameter analysis (e.g., pH, EC, C/N ratio, respiration rate) to precisely track compost maturity and stability. This level of detail is vital for applications requiring high-performance compost, offering unprecedented control over the final product’s quality.

- Cirkulär ekonomiintegration: Composting is increasingly recognized as a cornerstone of the circular economy model. It plays a crucial role in resource recovery from organic waste, returning valuable nutrients to the soil and reducing reliance on virgin materials. This aligns seamlessly with corporate sustainability goals and contributes to a more resilient and regenerative agricultural system, as highlighted by Veransa.com. The integration of composting into broader waste-to-resource strategies, including bio-energy, further solidifies its future importance.

Embrace advancements in compost assessment for future-proofed, sustainable B2B operations.

Vanliga frågor (FAQs)

How can hospitality businesses prevent sourcing phytotoxic compost? ▼

Hospitality businesses should prioritize suppliers with third-party certifications like the US Composting Council’s STA program, ensuring compost undergoes rigorous phytotoxicity testing before procurement.

What are the key indicators of contaminated compost for foodservice operations? ▼

Foodservice operations should look for physical contaminants like plastics or glass, unusual chemical odors, or a lack of uniform decomposition, indicating poor source separation and quality control.

How does inconsistent compost quality impact large-scale landscaping projects? ▼

Inconsistent compost quality leads to unpredictable plant growth, potential crop damage, and increased operational costs for re-work or sourcing alternative materials, delaying project completion.

What is the ideal C:N ratio for mature compost? ▼

Mature compost should ideally have a Carbon-to-Nitrogen (C:N) ratio between 10:1 and 20:1, ensuring stable nutrient release without causing nitrogen lock-up in the soil.

Why is temperature monitoring crucial in industrial composting? ▼

Temperature monitoring ensures the compost reaches thermophilic temperatures (120-150°F or 49-66°C) necessary to kill pathogens and weed seeds, meeting regulatory standards for safe use.FAQs address common compost quality concerns with actionable B2B solutions.

Slutsats

Understandinghow to know if compost is badis not merely an operational detail but a strategic necessity for B2B entities committed to sustainability, operational efficiency, and long-term profitability. By diligently recognizing the critical indicators—from immediate sensory and visual cues to advanced chemical and biological analyses—and by embracing industry standards and certifications, organizations can proactively mitigate significant risks.

Investing in verified, high-quality compost not only ensures compliance with increasingly stringent environmental regulations but also unlocks substantial operational and environmental benefits, including enhanced crop yields, reduced input costs, and a strengthened brand reputation. This strategic approach secures your supply chain and contributes directly to your corporate sustainability goals. To further integrate sustainable practices into your procurement, consider exploring solutions likeBPI certified compostable straws, which contribute to a cleaner compost stream and circular economy initiatives. Request a comprehensive compost quality assessment guide today to fortify your supply chain and accelerate your sustainability transformation before evolving market demands and regulatory pressures take full effect.Prioritizing quality compost is a strategic move for sustainable B2B operations and profitability.